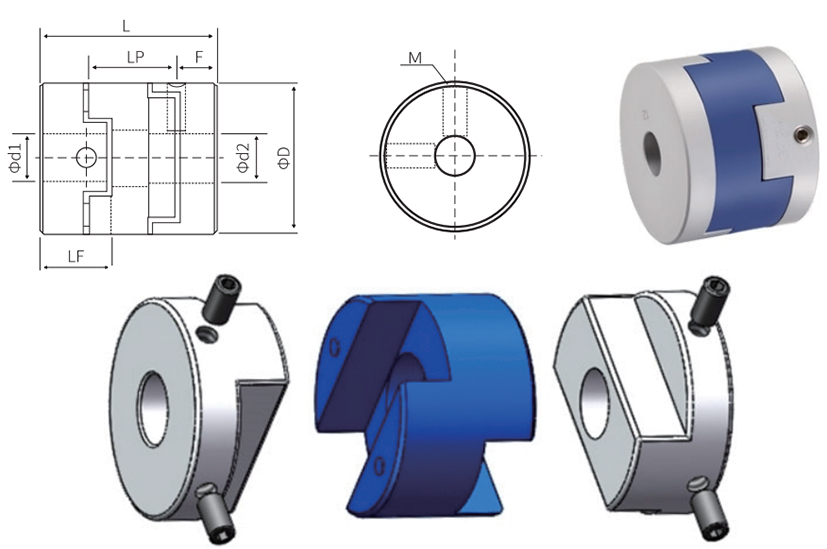

Oldham Couplings, Body AL, Elastic PA66

| talahanayan ng sukat | mm | |||||||

| Modelo | Karaniwang laki ng panloob na diameter ng DL / D2 | ΦD | L | LF | LP | F | M | Paghihigpit ng metalikang kuwintas (nm) |

| GL-16X18 | 4-5-6-6.35-7-8 | 16 | 18 | 7.1 | 12 | 3.0 | M3 | 1.2 |

| GL-20X23 | 5-6-6.35-7-8 | 20 | 23 | 9 | 12.7 | 4.5 | M4 | 1.7 |

| GL-20X25 | 5-6-6.35-8-9-9.525-10 | 20 | 25 | 10.1 | 12.7 | 3.0 | M4 | 2.5 |

| GL-25X28 | 5-6-8-9-9.525-10-11-12-14 | 25 | 28 | 21 | 17.7 | 2.8 | M4 | 2.5 |

| GL-32X33 | 5-6-8-9-9.525-10-11-12-12.7-14-15-16 | 32 | 33 | 14 | 20 | 3.4 | M4 | 2.5 |

| GL-40X32 | 8-9-9.525-10-11-12-12.7-14-15-16-17-18-19-20 | 40 | 32 | 14 | 20.3 | 3.2 | M4 | 2.5 |

| GL-44X46 | 8-9-9.525-10-11-1212.7-14-15-16-17-18-19-20-22 | 44 | 46 | 20.7 | 18.4 | 3.5 | M5 | 5 |

| GL-50X38 | 10-12-12.7-14-15-16-17-18-19-20-22-24-25 | 50 | 38 | 16.5 | 22.35 | 3.8 | M5 | 5 |

| GL-55X57 | 10-12-12.7-14-15-16-17-18-19-20-22-24-25-28-30-32 | 55 | 57 | 26.2 | 25.8 | 7.8 | M5 | 5 |

| GL-63X47 | 14-15-16-17-18-19-20-22-24-25-28-30-32 | 63 | 47 | 21 | 25.8 | 6.0 | M6 | 8 |

| GL-70X77 | 16-17-18-19-20-22-24-25-28-30-32-25-38-40 | 70 | 77 | 37 | 25 | 13.5 | M8 | 20 |

Teknikal na parameter

| Teknikal na parameter | mm | |||||||

| Modelo | Na-rate na metalikang kuwintas (Nm) | Pinahihintulutang eccentricity (mm) | Pinapayagan ang anggulo ng pagpapalihis (∠.) | Pinapayagan ang axial deviation (mm) | Pinahihintulutang bilis (RPM) | Static torsional stiffness (Nm/rad) | Moment of inertia (Nm) | timbang ng pagkabit (g) |

| GL-16X18 | 0.7 | 0.8 | 3 | ±0.2 | 9000 | 30 | 3.0X10-7 | 6 |

| GL-20X23 | 1.2 | 1.5 | 3 | ±0.2 | 3100 | 60 | 1.0X10-6 | 14 |

| GL-20X25 | 1.25 | 1.2 | 3 | ±0.2 | 7000 | 58 | 3.0X10-7 | 18 |

| GL-25X28 | 2 | 1.6 | 3 | ±0.2 | 6000 | 130 | 2.8X10-6 | 25 |

| GL-32X33 | 4.5 | 2 | 3 | ±0.2 | 4800 | 270 | 8.9X10-5 | 44 |

| GL-40X32 | 9 | 2.4 | 3 | ±0.2 | 3600 | 520 | 2.1X10-5 | 81 |

| GL-44X46 | 12 | 2.8 | 3 | ±0.2 | 3500 | 560 | 3.8X10-5 | 136 |

| GL-50X38 | 19 | 2.6 | 3 | ±0.2 | 3000 | 800 | 6.0X10-5 | 142 |

| GL-55X57 | 22 | 3.3 | 3 | ±0.2 | 2800 | 795 | 9.9X10-5 | 255 |

| GL-63X47 | 33 | 3 | 3 | ±0.2 | 2500 | 1200 | 2.1X10-4 | 320 |

| GL-70X77 | 56 | 3.8 | 3 | ±0.2 | 2500 | 1260 | 3.9X10-4 | 445 |

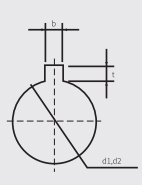

Talahanayan ng paghahambing ng mga sukat ng pagpoproseso ng keyway

| Dimensyon ng diameter ng baras | Standard na sukat ng machining ng keyway | Laki ng keyway | Karaniwang pagguhit ng pagpoproseso ng keyway | |||

| dl/d2 | b | t | (bxh) |

| ||

| Lapad ng slot | pagpaparaya | lalim ng slot | pagpaparaya | |||

| Φ6-Φ7.9 | 2 | ±0.0125 | 1.0 | ±0.10 | 2X2 | |

| Φ8-Φ10 | 3 | ±0.0150 | 1.4 | 3X3 | ||

| Φ10.1-Φ12 | 4 | 1.8 | 4X4 | |||

| Φ12.1-Φ17 | 5 | 2.3 | 5X5 | |||

| Φ17.1-Φ22 | 6 | ±0.0180 | 2.8 | 6X6 | ||

| Φ22.1-Φ30 | 8 | 3.3 | ±0.20 | 8X7 | ||

| Φ30.1-Φ38 | 10 | ±0.0215 | 3.3 | 10X8 | ||

| Φ38.1-Φ44 | 12 | 3.8 | 12X8 | |||

| Φ44.1-Φ50 | 14 | 4.3 | 14X9 | |||

| Φ50.1-Φ58 | 16 | 4.4 | 16X10 | |||

| Φ58.1-Φ65 | 18 | 4.4 | 18X11 | |||

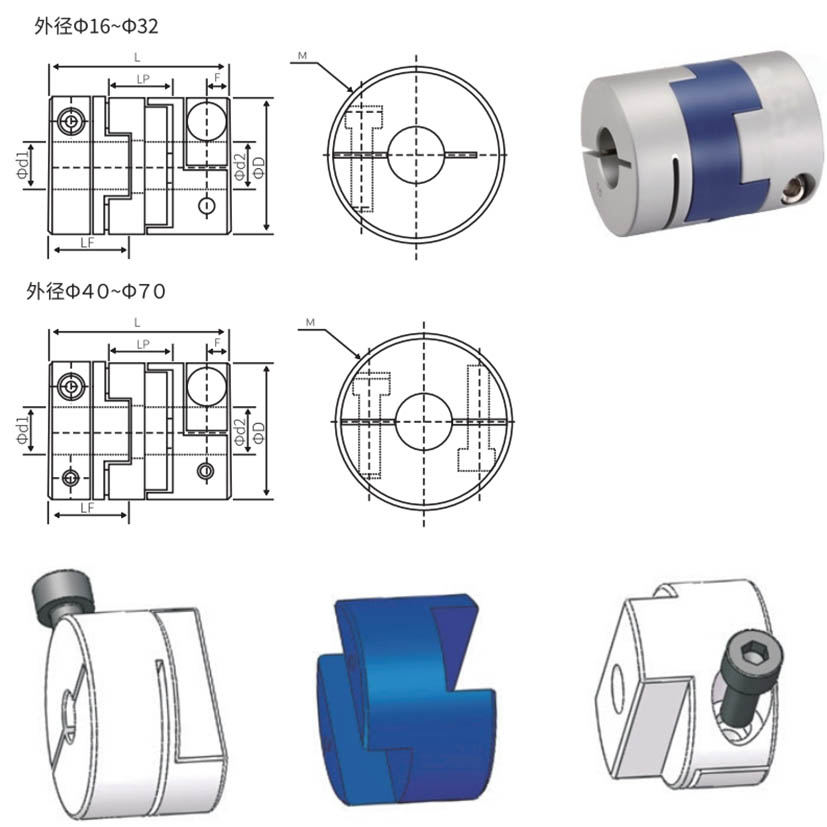

Talaan ng sukat ng balangkas

| Talaan ng sukat ng balangkas | mm | |||||||

| Modelo | Karaniwang laki ng panloob na diameter ng DL / D2 | ΦD | L | LF | LP | F | M | Paghihigpit ng metalikang kuwintas (nm) |

| GLC-16X29 | 4-5-6-6.35 | 16 | 29 | 12.5 | 12 | 3 | M2.5 | 0.8 |

| GLC-20X33 | 5-6-6.35-7-8 | 20 | 33 | 14.1 | 12.7 | 3.8 | M2.5 | 0.8 |

| GLC-25X39 | 5-6-6.35-8-9-9.525-10-11-12 | 25 | 39 | 16.9 | 17.7 | 3.9 | M3 | 1.2 |

| GLC-32X45 | 5-6-8-9-9.525-10-11-12-12.7-14-15-16 | 32 | 45 | 20 | 20 | 4.5 | M4 | 2.5 |

| GLC-40X50 | 8-9-9.525-10-11-12-14-15-16-17-18-19 | 40 | 50 | 23 | 20.3 | 5.5 | M5 | 5 |

| GLC-44X46 | 8-9-9.525-10-11-12-14-15-16-17-18-19-20-22 | 44 | 46 | 20.7 | 18.4 | 7 | M5 | 5 |

| GLC-50X53 | 10-11-12.7-14-15-16-17-18-19-20-22-24 | 50 | 53 | 24.2 | 22.35 | 7.5 | M6 | 8 |

| GLC-50X58 | 10-11-12.7-14-15-16-17-18-19-20-22-24 | 50 | 58 | 26.5 | 22.35 | 6.3 | M6 | 8 |

| GLC-55X57 | 10-11-12.7-14-15-16-17-18-19-20-22-24-25-28 | 55 | 57 | 26.2 | 25.8 | 6.3 | M6 | 8 |

| GLC-63X71 | 14-15-16-17-18-19-20-22-24-25-28-30-32 | 63 | 71 | 32.8 | 26.2 | 7.8 | M8 | 20 |

| GLC-70X77 | 14-15-16-17-18-19-20-22-24-25-28-30-32-35-38 | 70 | 71 | 37 | 25 | 7.7 | M8 | 20 |

Teknikal na parameter

| Teknikal na parameter | mm | ||||||||

| Modelo | Na-rate na metalikang kuwintas (Nm) | Pinahihintulutang eccentricity (mm) | Pinapayagan ang anggulo ng pagpapalihis (∠.) | Pinapayagan ang axial deviation (mm) | Pinahihintulutang bilis (RPM) | Static torsional stiffness (Nm/rad) | Moment of inertia (Nm) | Pagsasama ng timbang (g) | |

| GLC-16X29 | 0.7 | 0.8 | 3 | ±0.2 | 9000 | 30 | 3.5X10-7 | 12 | |

| GLC-20X33 | 1..2 | 1.2 | 3 | ±0.2 | 7000 | 58 | 1.5X10-6 | 19 | |

| GLC-25X39 | 2 | 1.6 | 3 | ±0.2 | 6000 | 130 | 3.2X10-6 | 35 | |

| GLC-32X45 | 4.5 | 2 | 3 | ±0.2 | 4800 | 270 | 1.5X10-5 | 67 | |

| GLC40X50 | 9 | 2.4 | 3 | ±0.2 | 3600 | 520 | 4.2X10-5 | 114 | |

| GLC-44X46 | 12 | 2.5 | 3 | ±0.2 | 3500 | 800 | 4.5X10-5 | 140 | |

| GLC-50X53 | 19 | 2.6 | 3 | ±0.2 | 3000 | 800 | 1.0X10-4 | 190 | |

| GLC-50X58 | 19 | 3 | 3 | ±0.2 | 3000 | 800 | 1.1X10-4 | 215 | |

| GLC-55X57 | 25 | 3.2 | 3 | ±0.2 | 3000 | 900 | 1.3X10-5 | 260 | |

| GLC-63X71 | 33 | 3 | 3 | ±0.2 | 2550 | 1200 | 3.5X10-4 | 455 | |

| GLC -70X77 | 56 | 3.5 | 3 | ±0.2 | 2500 | 1260 | 4.1X10-4 | 520 | |

Ang mga Oldham coupling ay tatlong-piraso na flexible shaft coupling na ginagamit upang kumonekta sa mga driving at driven shaft sa mga mechanical power transmission assemblies. Ang mga flexible shaft coupling ay ginagamit upang kontrahin ang hindi maiiwasang misalignment na nangyayari sa pagitan ng mga konektadong shaft at, sa ilang mga kaso, upang sumipsip ng shock. Material: Ang mga Uub ay nasa Aluminium, ang nababanat na katawan ay nasa PA66.